Since 1966

we make yours

projects

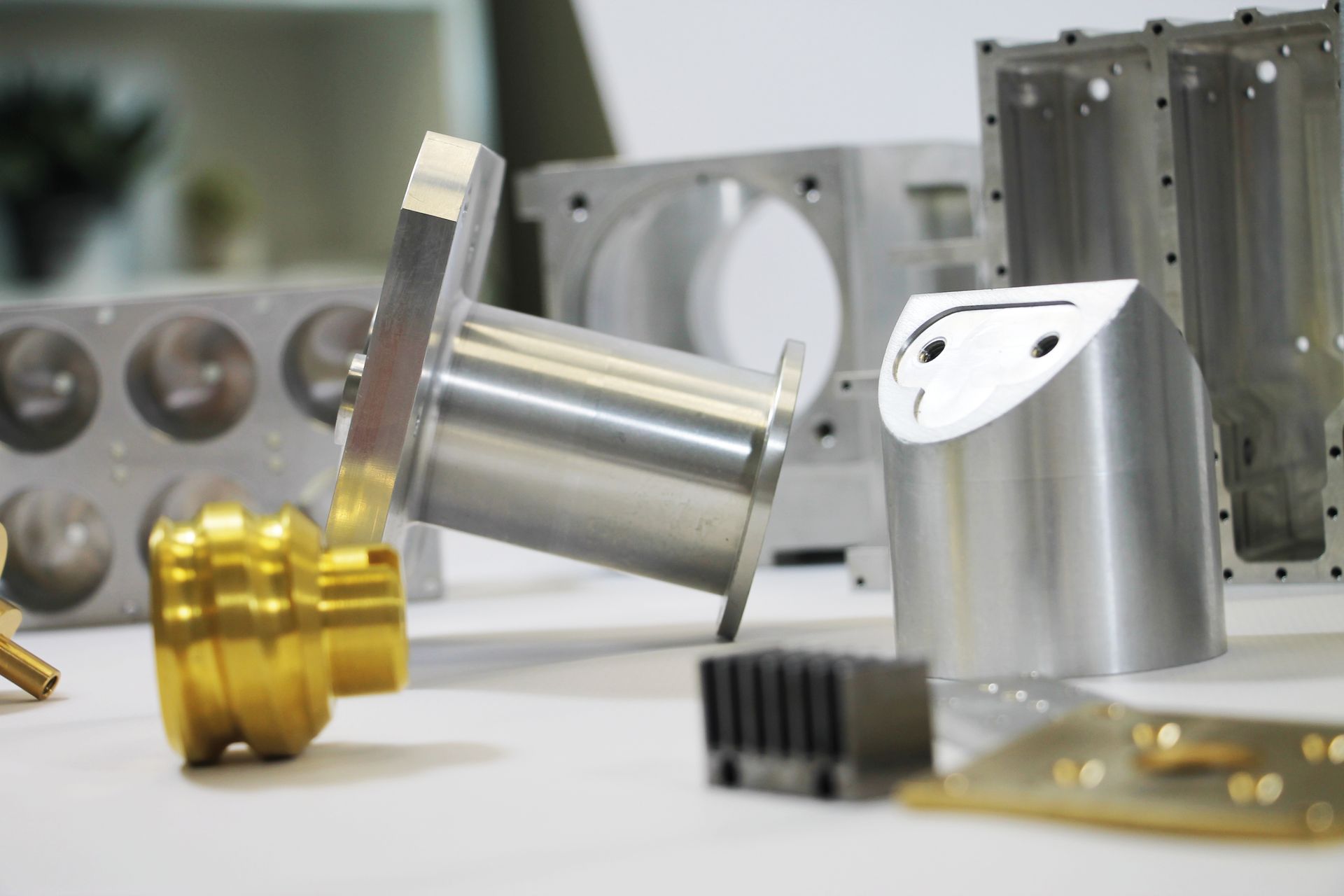

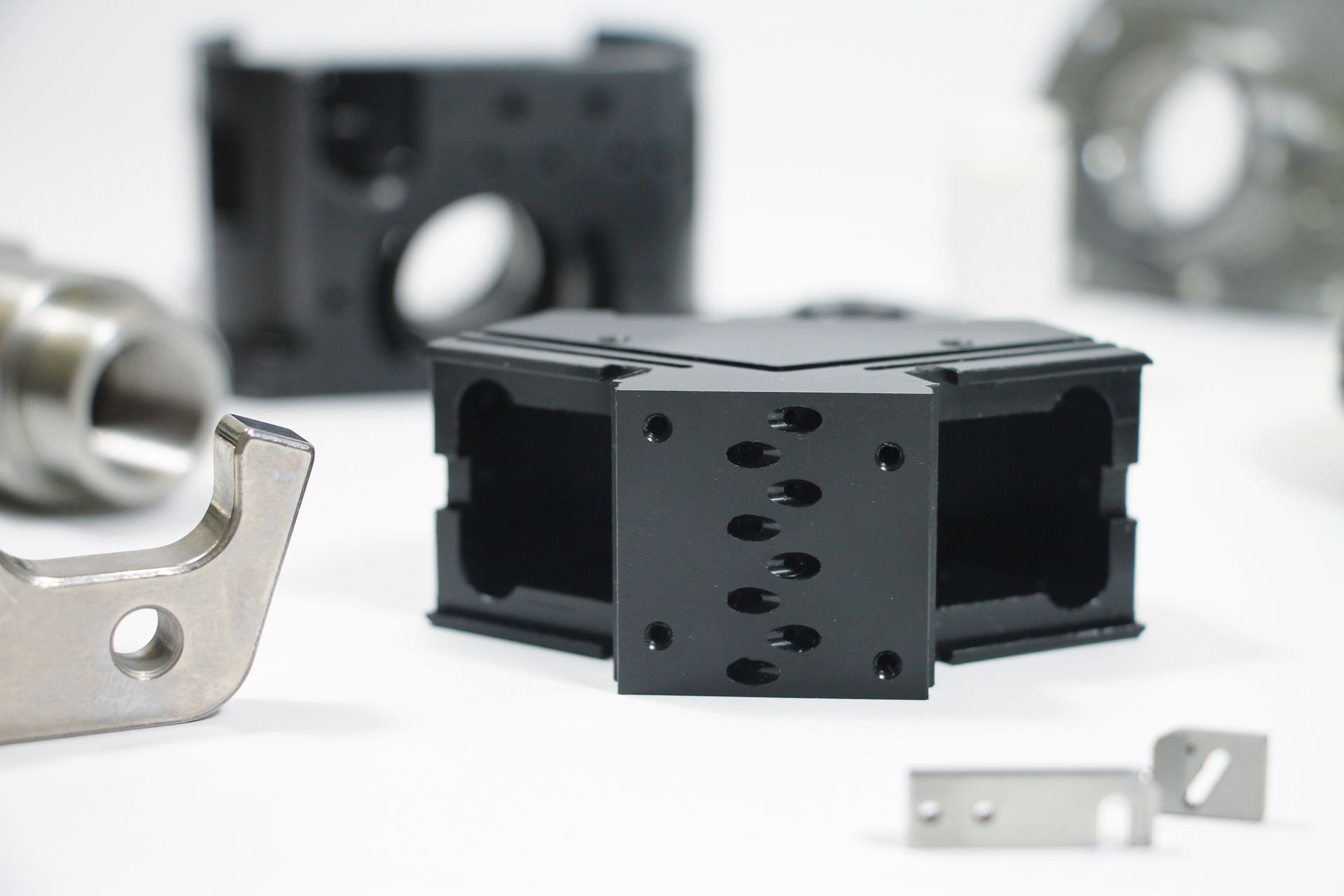

Supported by two cad-cam software we are able to obtain the most complex geometries to satisfy every type of request.

In addition to repetitive and mass production of small to medium batches, we are also able to produce 1-piece samples.

5-AXIS MACHINING

Reliability, speed and Japanese precision for high-performance work

The machine, in addition to being compact, is equipped with rotation and inclination axes which allow turning and milling processes to be carried out in a single positioning.

SUPPLY SECTORS

IRMA, working for third parties on commission, does not produce pieces of its own design but based on the customer's drawings. In its "drawing portfolio" there are over 5000 drawings created over the years.

The main supply sectors are:

- ELECTROMECHANICS

- TELECOMMUNICATIONS

- HANDLING and VACUUM

- OTHERS

QUALITY

THE MEASUREMENT EQUIPMENT IS COMPLETE TO ENSURE ANY TYPE OF CONTROL

The company, in addition to being ISO 9001:2015 certified, is approved by the most important customers through a process that periodically checks the entire production process with extremely high-performance audits.

IRMA

MECHANICAL WORKING MACHINING:

a family history

IRMA FOR THE ENVIRONMENT

Sustainability: a fundamental concept for the company

IRMA has always focused attention on two aspects that we believe are fundamental for company growth and closely linked: PEOPLE & ENVIRONMENT

In recent decades, the company has set itself the objective of investing part of its capital in energy efficiency and in reducing the impact of oil mist emissions created by machinery by installing a centralized extraction system in the workshop.