WE GUARANTEE

EVERY TYPE OF CONTROL

The measurement instrumentation is complete to guarantee every type of control

The company, in addition to being ISO 9001:2015 certified, is approved by the most important customers through a process that periodically checks the entire production process with extremely high-performance audits.

Supported by the ERP, the traceability of the work order is guaranteed by effective management of the process, ensuring at all times the traceability of the raw material, the work cycle, the machines used and, if applicable, the heat treatments and/or superficial.

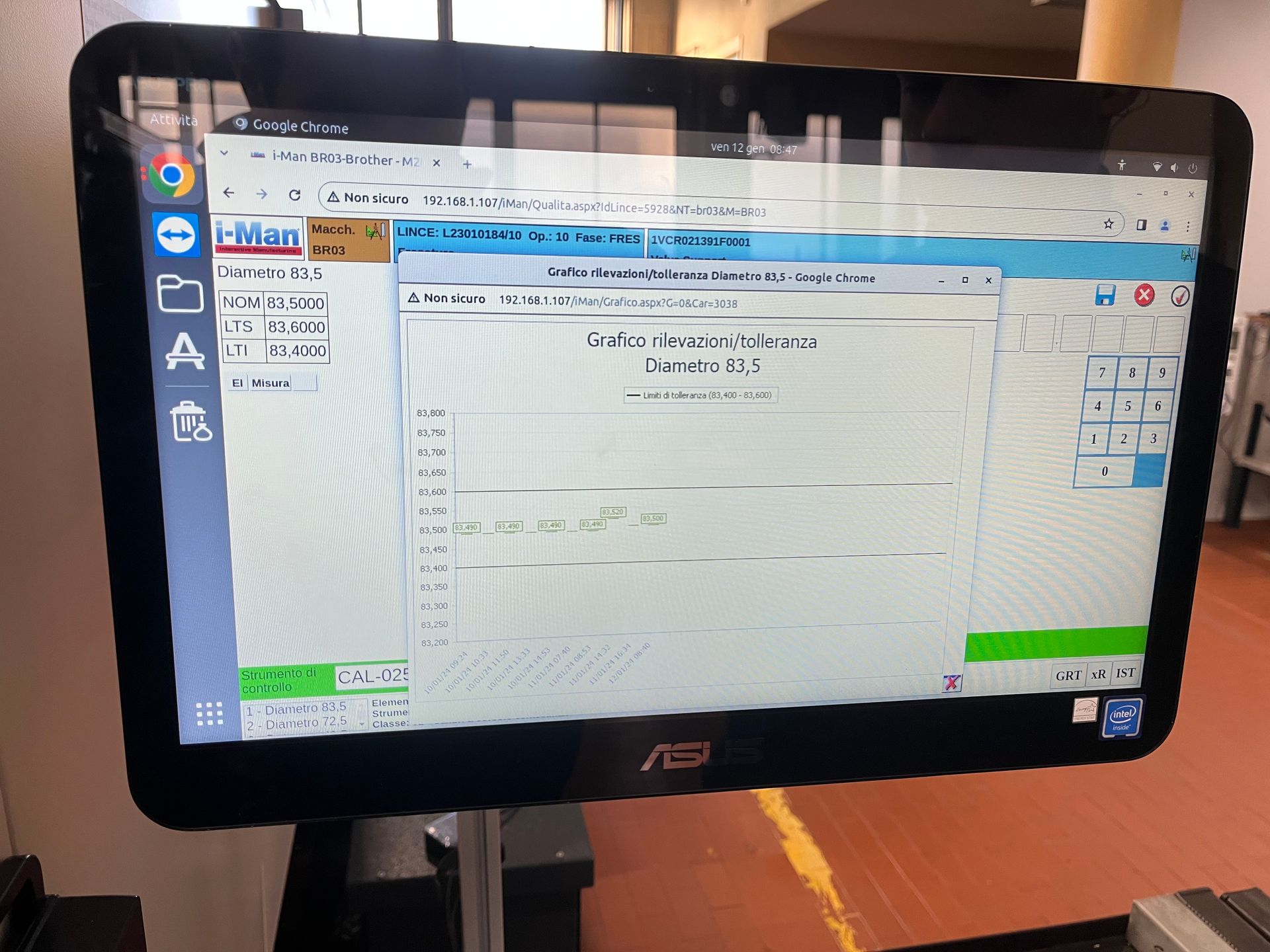

Checks on the piece are carried out by the quality manager several times during the manufacturing cycle: in the "first piece" phase, on a random basis according to statistical criteria during the production of the batch and before final delivery to the customer. Furthermore, if requested, there is the possibility of recording, through the MES station, the quality controls carried out on board the machine by the operator according to control plans created ad hoc.

The instruments supplied to the quality department are the most varied: analogue and digital calipers, rings, smooth and threaded pads, analogue and digital micrometers, centesimals, sets of Johnson blocks, comparators, roughness meter, Mitutoyo digital altimeter, Baty vertical profile projector, dimensional measuring machine using Keyence images.

These are all cataloged and managed within the ERP in order to always guarantee reliability and traceability.

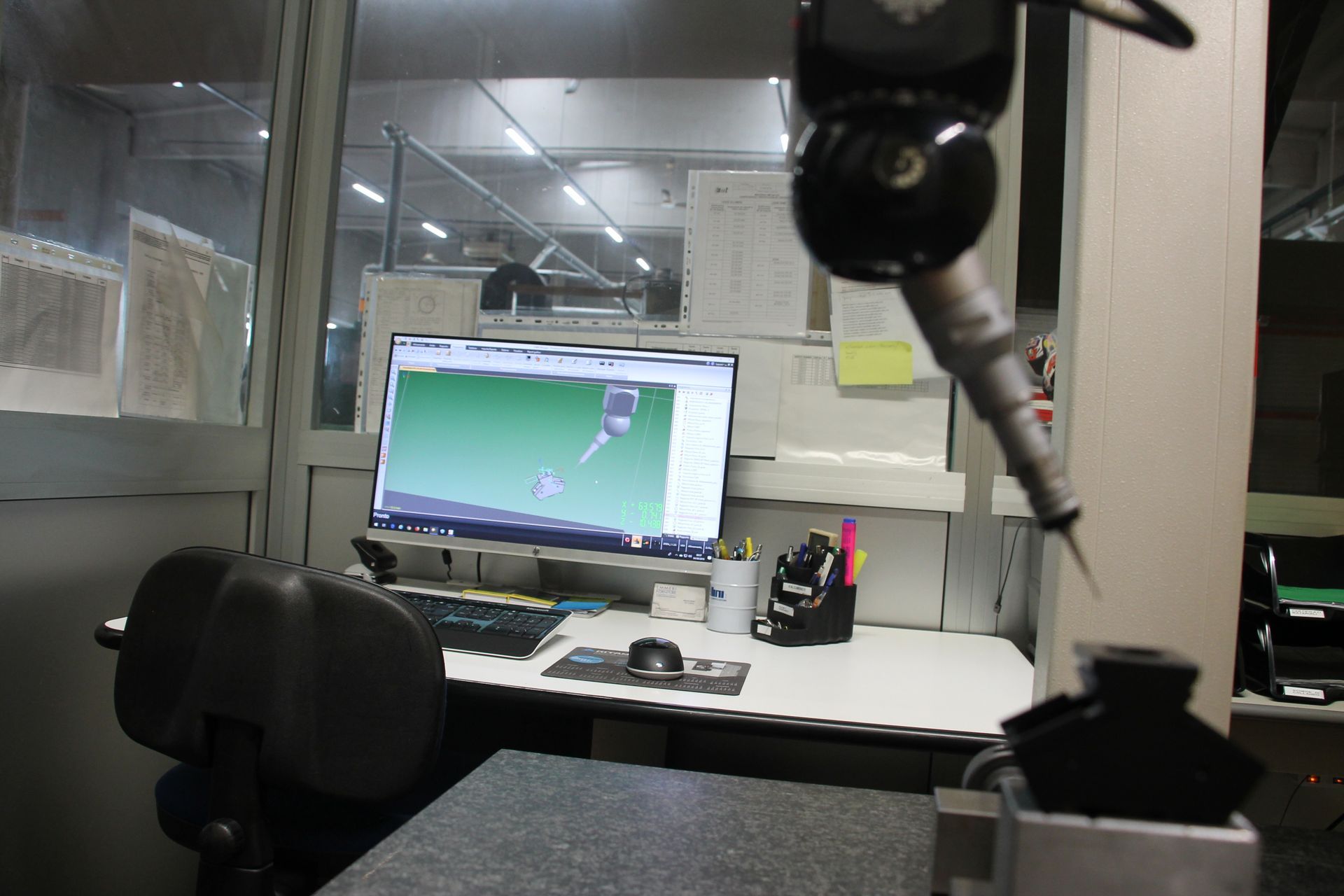

The instrumentation is completed by a Dea Mistral three-dimensional measuring machine with a 6-station rack which underwent a hardware and software retrofit in 2019, in order to quickly obtain measurement cycles by importing the 3D file, for immediate use, even during the control of the “first piece”.